10 Commonly Asked Questions About Modular Homes

As more people discover the benefits of modular homes, we’ve answered ten of the most commonly asked questions at Modscape + Modbotics.

1. What is a modular home?

A modular home is designed and built as a series of volumetric modules in a controlled factory environment. Once complete, the modules are transported to site and assembled to form the finished home.

This approach allows for greater quality control, faster build times and minimal disruption to the site—with most Modscape homes built in just 12–15 weeks.

2. Will I need a permit for my modular home?

Yes permits are required for a modular home but every project is unique so permit requirements can differ.

Not all modular house projects require a Planning Permit but every project requires a Building Permit.

A Planning Permit (or Development Application if your project is in NSW) is issued by your local Council in accordance with a planning scheme. You can contact the planning department of your local Council to determine whether you will require a Planning Permit for your prefab home.

Regardless of whether you need a Planning Permit or not, your modular home project will require a Building Permit. A Building Permit, also known as a Construction Permit, is a document issued by an independent and registered building surveyor.

3. Can I build a modular home on a sloping block?

Sloping or uneven sites are easily accommodated, as our modular homes are not built on a conventional slab. Depending on site conditions, we use either screw piles or a structural steel frame to support the modules—reducing excavation, avoiding extensive levelling, and leaving a lighter footprint on the land. The optimal solution is confirmed after a site inspection and review of surveys.

4. How long does it take to complete the home once the modules arrive on site?

With most of the construction completed in our factory, on-site time is significantly reduced.

Approximately three to four weeks before installation, our team prepares the site—carrying out any demolition, service works and installation of the footings. This takes place while the home is being built in the factory. The home is then installed by crane, typically within a single day, with final detailing and service connections completed within two to four weeks—ready for move-in.

5. Can I build a modular home in a high bushfire prone area?

Yes. Our steel frame construction enables us to build in any Bushfire Attack Level (BAL) zone, including Flame Zone. While some material selections may vary for higher BAL ratings, the structure remains consistent across all conditions.

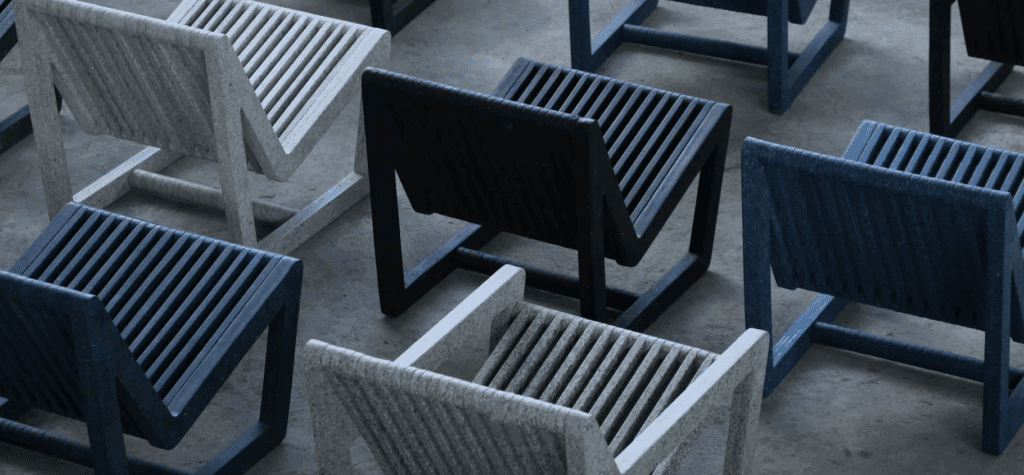

6. What are the design options available in a modular home?

Modular construction offers exceptional design flexibility. Our steel-frame system allows modules to span large distances, enabling open-plan layouts and generous spaces free from internal columns.

Modules can be combined in countless ways to create unique configurations of any scale or shape. From angular walls and pitched roofs to more complex or sculptural forms, the design possibilities are extensive.

Each home arrives on site with the majority of finishes complete—including painting, tiling, and joinery—ensuring exceptional quality and a streamlined installation process. Any elements that can’t be transported fully assembled, are completed on site after installation.

7. How are the modules connected on site?

Once completed, our housing modules are transported individually to your site, where they are placed into position, either by crane or truck, and then grounded using footings. The modules are then bolted together with a seamless finish on the floor and a completely waterproof expressed joint or reveal between wall and ceiling joins.

8. How does modular construction improve cost efficiency?

Building in a controlled factory environment removes many of the uncertainties such as weather delays and trade scheduling. This efficiency, combined with the high level of documentation required for modular design, delivers greater cost certainty and refined design outcomes.

9. What should I know about financing a modular home?

In our experience, once lenders understand our design approach and construction process, they recognise the quality if our modular build. The result is a premium home—built to the same standards as any traditional house, yet delivered faster and with less risk.

Engaging a knowledgeable mortgage broker is recommended, along with providing clear plans, specifications, and timelines.

10. What heating and cooling options do I have?

There are no limitations to the heating and cooling options available to you for a modular build. Because we transport our homes all across Australia every client has different climatic requirements and preferences. Open wood or gas fireplaces and hydronic heating are all popular heating options while ceiling fans and, sometimes, air-conditioning systems are the most common cooling options. We work with you to establish the best cost and energy solution for your sustainable home.

Have more questions about Modscape’s modular homes? Contact our team to discuss further.