10 Commonly Asked Questions Modscapes Modular Homes

Despite the growing popularity and greater appreciation of the prefabricated construction industry, there are still a lot of questions and misconceptions about modular homes. Here are 10 of the most commonly asked questions we get at Modscape.

1. What Are Modular Homes?

Clients who are new to the concept of modular construction often ask Modscape, “is a modular home the same as a prefabricated build?” And, “what are the main differences between a modular home and a traditional home?”

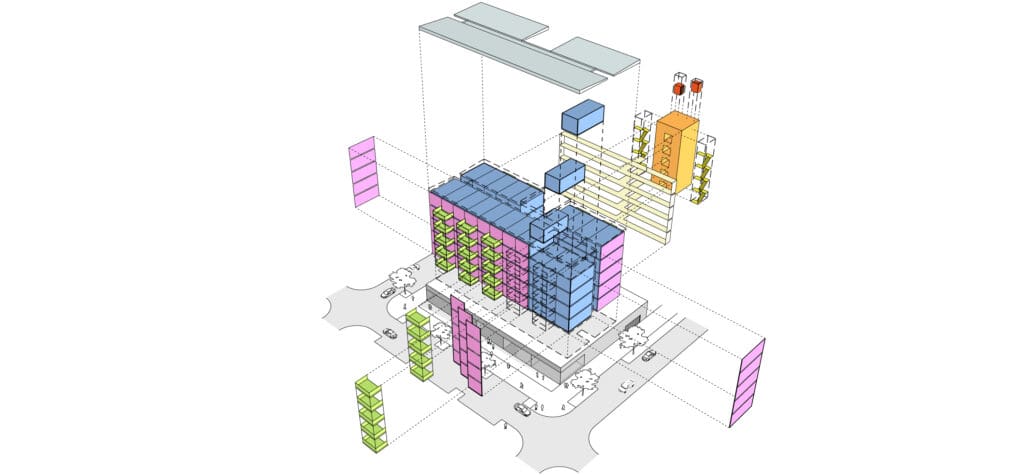

In essence, all modular builds are a form of prefab construction. Prefab or prefabricated is an umbrella term for off-site construction that refers to building a structure in a factory before it is assembled and installed onsite. Modular construction is just one category of prefabricated construction.

A modular home is one that is built in a factory. The finished modules are transported to site where they are assembled to form a complete home. One of the beauties of a Modscape modular home is that it is built and installed in 12 weeks.

2. Will I need a permit for my modular home?

Yes permits are required for a modular home but every project is unique so permit requirements can differ.

Not all modular house projects require a Planning Permit but every project requires a Building Permit.

A Planning Permit (or Development Application if your project is in NSW) is issued by your local Council in accordance with a planning scheme. You can contact the planning department of your local Council to determine whether you will require a Planning Permit for your prefab home.

Regardless of whether you need a Planning Permit or not, your modular home project will require a Building Permit. A Building Permit, also known as a Construction Permit, is a document issued by an independent and registered building surveyor.

3. Can I build a modular home on a sloping block?

Sloping sites are no issue for us as we don’t pour a slab. This negates the need for necessarily having to excavate and level the site. We either use screw piles or create a steel frame for the modules to sit on. These methods are a lot lighter on the land. We would be able to determine the best method following a site inspection and obtaining the necessary surveys.

4. For a modular build, how long will the onsite works take?

As the majority of the works are undertaken at the factory, there is minimal time spent on site for a modular build.

The Modscape team would arrive 3-4 weeks prior to the installation date to conduct any demolition, prepare the site for services and install the screw pile footings. This happens concurrently with the house build at our factory in Melbourne (See inside our factory and design office). Installation of the home using a crane typically takes one day, and about 2-4 weeks later our team will have completed the last finishing works and completed the connection to your site services – now you’re ready to move in.

Minimal time on site is a big plus for those wishing to knock down their current house and rebuild. Clients spend less time and money on renting as the total downtime is condensed – the majority of our clients are out of a house 5-7 weeks total.

5. Can I build a modular home in a high bushfire prone area?

Yes. With our steel frame construction we can build right up to, and including, Flame Zone. With a high Bushfire Attack Level (BAL) rating there can be certain material selections that need to be made, but with Modscape we don’t need to change your structure at all.

6. How much design input can I have?

The process of creating your dream home is highly planned but flexible in outcome. It’s a very collaborative approach between yourselves and our in-house design team (or an external architect of your choosing). Each project is unique and specific to your site, reflecting your projects spatial requirements and budget. Design and finish options are limitless – but what is certain is that every design is the result of our design team’s genuine collaboration with you.

As part of the Modscape process you will be presented with detailed elevations of your interiors and our team will guide you through the selection of colours, fixtures, fittings, lighting and joinery for your new home.

7. Are there any limitations in the design/ materials used in a modular home?

The misconception that prefab has no flexibility in design outcome is a myth. Design-wise, anything is possible. The steel frame modules can span large distances which gives us great flexibility in the design and means we can easily create large open spaces unencumbered by columns.

It’s true that building in modules tends to lend itself to box-like forms. But modules can be arranged in a myriad of ways to create any configuration of space, of any shape and size. We can build angular walls, pitched roofs and can even combine modules to create elliptical form.

We transport our homes to site with the majority of works complete. All of the painting, tiling, joinery etc. is done. This ensures we achieve a high level of quality control and reduces the amount of time required onsite. Any elements that can’t be transported complete – say a stone fireplace – would just need to be completed onsite post-installation.

8. Are modular homes more cost-effective to build?

With a modular home the risks of time delays due to inclement weather and trades not turning up on site are mitigated thanks to the controlled factory environment. The rapid construction forces a high level of documentation – which in turn means a higher degree of design resolution and greater control of the costs.

9. Is it hard to get a loan for a modular home?

Despite the numerous advantages of building modular, financing a modular build can sometimes be tricky as some lending institutions can be reluctant to provide loans for an off-site build. The tendency is to assume an antiquated perspective of modular construction and associate it with more of a kit home idea.

At Modscape we’ve found that once the providers understand our concept and model they have a different view.

The finished product is a new home, no different to any other home in the marketplace. The quality of construction is high and the speed reduces the risk.

Approaching a mortgage broker with plans, specifications and a project program in place is a good idea. Having a significant deposit makes it easier, as does equity in the land or other property.

10. What heating and cooling options do I have?

There are no limitations to the heating and cooling options available to you for a modular build. Because we transport our homes all across Australia every client has different climatic requirements and preferences. Open wood or gas fireplaces and hydronic heating are all popular heating options while ceiling fans and, sometimes, air-conditioning systems are the most common cooling options. We work with you to establish the best cost and energy solution for your sustainable home.

Have more questions about Modscape’s modular homes? Contact our team to discuss further.